High crystal quality for demanding power electronics

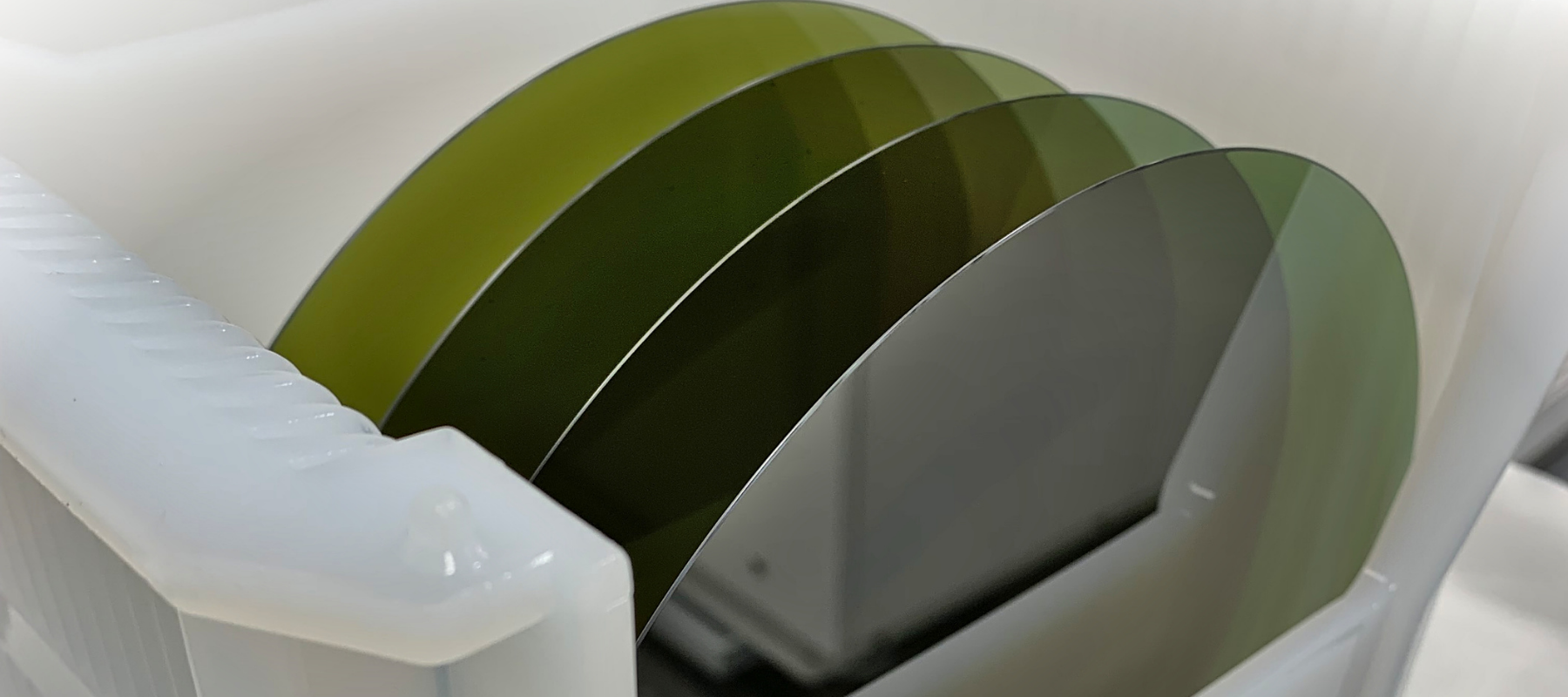

As transportation, energy and industrial markets evolve, demand for reliable, high performance power electronics continues to grow. To meet the needs for improved semiconductor performance, device manufacturers are looking to wide bandgap semiconductor materials, such as our 4H SiC Prime Grade portfolio of 4H n -type silicon carbide (SiC) wafers.

Reliable and Ready

SK siltron css 150 mm SiC wafers offer device manufacturers a consistent, high quality substrate for developing high-performance power devices. Our SiC substrates are produced from crystal ingots of the highest quality using proprietary state-of-the art physical vapor transport (PVT) growth techniques and computer-aided manufacturing (CAM). Advanced wafer manufacturing techniques are used to convert ingots into wafers to ensure the consistent, reliable quality you need.

Key features

- Optimizes targeted performance and total cost of ownership for next generation power electronics devices

- Large diameter wafers for improved economies of scale in semiconductor manufacturing

- Range of tolerance levels to meet specific device fabrication needs

- High crystal quality

- Low defect densities

Sized for improved production

With the 150 mm wafer size, we offer manufacturers the ability to leverage improved economies of scale compared with 100 mm device fabrication. Our 150 mm SiC Wafers offer consistently excellent mechanical characteristics to ensure compatibility with existing and developing device fabrication processes.

Customized to meet your needs

Our SiC material can be customized to meet the performance and cost requirements of device design needs. We have the capability to produce high quality wafers for next generation devices with low defect densities as low as MPD ≤ 0.1 cm -2, TSD ≤ 400 cm- 2 and BPD ≤ 1,500 cm -2.

Learn more from our technical PDF on 150 mm Silicon Carbide Wafers

Material Properties

Note: Please contact your local sales office or SK siltron css technical support before noting final specifications on these products.

150mm SiC wafers

| Product Metric | Prime |

| Diameter, mm | 149.8 – 150.2 |

| Thickness, µm | 325 – 375 |

| Primary flat length,(1) mm | 45 – 50 |

| Bow, µm | ±10 |

| Warp, µm | ≤30 |

| TTV, µm | ≤10 |

| SBIR, µm | ≤2 |

| Visible scratches, mm | ≤150 |

| Resistivity, ohm-cm | 0.014 – 0.024 |

| Dislocation density,(4) (cm-2) | |

| TED (mean) | ≤9,000 |

| BPD (mean) | ≤3,000 |

| MPD, cm-2 | ≤0.5 |

Please contact us for information on our 200mm SiC wafers.

How Can We Help You?

Let us put our materials expertise, application knowledge and processing experience to work for you. To tell us about your performance, design and manufacturing challenges, and learn more about how we can help you, contact us at sales@sksiltron.com.